The Dawn of Innovation (35 page)

Read The Dawn of Innovation Online

Authors: Charles R. Morris

But as the 1850s opened with a surge of new sales, the company's productivity could not keep pace. Locomotives were bigger, and part counts were risingâso were mistakes and missed deadlines. Baldwin and Baird began to rethink operations, and over the next twenty years the company became a model of a modern, World War Iâvintage, capital goods manufacturer.

The first step was the installation of a piecework payment system. That wasn't a matter of turning a switch, for there was no documentation on the discrete tasks performed in each shop or the value of each major process completed. It took a couple of years, but they worked it through. In general, the men liked it because they earned more. (Baldwin, unlike an Andrew Carnegie, did not use piece rates to reduce wages; if output was rising, he was happy to see the men earn more.) The foremen hated it because the implicit task standardization invaded the traditional independence of the shops.

The next challenge was the proliferation of locomotive designs.

bh

Parts counts were becoming unmanageable, and the craft-shop manufacturing culture meant that standard parts were rarely identical anyway. So-called standard parts emerging from the machine shops couldn't be fitted into standard boilers in the boiler shop without extensive reworking. To make matters worse, customers were complaining about the work required to make even the simplest repairs. Other shops had the same problems, but a high-volume producer like Baldwin

bi

could strangle on them.

bh

Parts counts were becoming unmanageable, and the craft-shop manufacturing culture meant that standard parts were rarely identical anyway. So-called standard parts emerging from the machine shops couldn't be fitted into standard boilers in the boiler shop without extensive reworking. To make matters worse, customers were complaining about the work required to make even the simplest repairs. Other shops had the same problems, but a high-volume producer like Baldwin

bi

could strangle on them.

Solving the parts snarl took more than a decade and required a complete rethinking and upgrading of the production system. The first step was to identify all the parts used in production and eliminate any unnecessary variation. All boilers have multiple water taps, for instance; absence a specific justification for a variance, all such parts should be identical. But to achieve that, the company had to choose the default tap, carefully specify it in a set of dimensioned engineering drawings, and then repeat that exercise for a couple of thousand or so more standard parts. By the early 1870s, there were standard, dimensioned drawings covering all important standard parts, with a comprehensive parts catalog. When a job was being laid out, all standard parts were specified by their catalog number.

Â

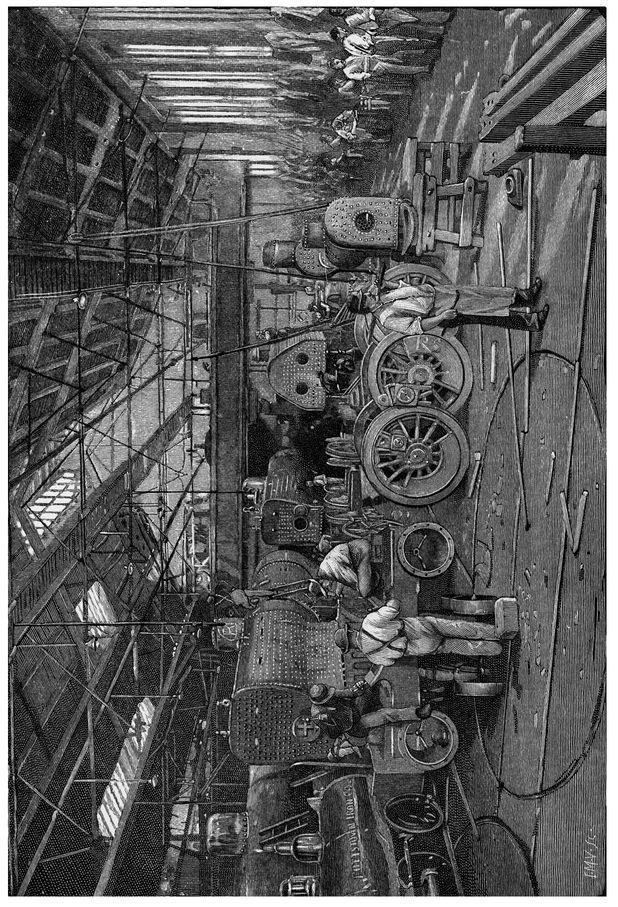

Bladwin Shop.

After all parts had been anufactires or received from its vendors, baldwin typically devotes two weeks to assembling each engine. Since avery engine was different, the erecting shop workers had to embody a broad range of skills. Even standard parts that were nomilally "interchangeable" were likely to require fitting just as gun parts did. The workers by the windows are filing parts The erecting shop was expanded to accommodate multiple engines in the early 1850s, and was regularly further axpanded as volumes increased. There are at least seven engines being worked on in this picture from 1869, which suggests the complexity of the parts acquisition and tracking challenge.

After all parts had been anufactires or received from its vendors, baldwin typically devotes two weeks to assembling each engine. Since avery engine was different, the erecting shop workers had to embody a broad range of skills. Even standard parts that were nomilally "interchangeable" were likely to require fitting just as gun parts did. The workers by the windows are filing parts The erecting shop was expanded to accommodate multiple engines in the early 1850s, and was regularly further axpanded as volumes increased. There are at least seven engines being worked on in this picture from 1869, which suggests the complexity of the parts acquisition and tracking challenge.

The last step was to gradually adopt armory-style gauging. Baldwin had a large cadre of skilled machinists and had long made almost all of its own machines, so it's likely that it made its own gauges as well. By the 1880s, locomotive makers were claiming that all their parts were “interchangeable,” although only subsets, like critical gears and power train parts, demanded the kind of high precision required by watchmakers or gun makers. All major railroads had sophisticated machine shops to manage repairs, and since replacement parts were typically installed in heavily used machinery, some fitting was almost always required.

The striking advances in productivity speak for themselves. But they had much more to do with management than with machinesâsimplifying designs, rationalizing the production and assembly process, and taking control of parts, specifications, and work sequences. Improved specification also allowed the company to experiment with “insourcing” the shops: bidding out contracts, usually to foremen, for delivering annual production according to a negotiated price schedule. On the whole, the experiment worked out well and was retained for many years, but the ground had been prepared by the years of work on standardization and work rationalization.

Baldwin offers yet another model of mass-production manufacturing. Like the Mitchell and Rammelsberg plant, it has a number of affinities with armory practice. But although it took full advantage of improvements in gauging, cutting tools, and materials quality, its operations were highly labor-intensive well into the twentieth century, with heavy reliance on general-purpose machinery in the hands of skilled workers.

The real story at Baldwin was not mechanization but its operations managementâthe product of an ultralean top management with deep experience on the shop floor. There were no outside “efficiency experts.” In the early twentieth century, indeed, Baldwin executives were extremely critical of Taylorism and the so-called scientific management movement. An 1879 visitor noted: “Owing to the magnitude of the establishment, a stranger would naturally suppose that it would require almost a regiment of Bosses and any amount of âbossing,' but such is not the case by any means. There are very few lookers on to be seen in the shops.... The proprietors, superintendents, gang, and track bosses all work themselves so there are very few, if any, drones in the hive.”

56

56

And it stayed lean for a long time. In 1910, when Baldwin had grown to 14,500 employees turning out 1,675 locomotives, most of enormous weight and complexity, the president, William Austin, normally spent half his working day in the drafting room checking drawings.

Corliss EnginesGeorge H. Corliss was a dominant figure in steam-engine technology in the second half of the nineteenth century. The son of an upstate New York physician, he had no university or technical training and is said not to have seen the inside of a machine shop before he was eighteen. But Corliss had the gift. Bored as a clerk in a country store, he invented a machine for sewing leather and patented it in 1843, when he was twenty-six. Hoping to develop prototypes, he went to Providence, a machining center, in 1844 and took a job as an assistant in a machine shop. The partners appreciated his acumen and encouraged him to shift his interest to steam. Within two years he was a full partner. By then Corliss had already conceived the mechanisms that one of his rivals, who later became an industry historian, called “the most famous steam engine that has appeared since the time of Watt.”

57

57

One of the machine-shop partners capitalized a new company to develop Corliss's ideas. Corliss got one-third interest plus royalty payments on sales, in return for his patents and a small capital contribution. The first

engine sold that same year for $8,600 without the boiler, and its success quickly led to several more sales. By the time of the final patent award in 1849, they were already building a new and expanded factory. The company was renamed the Corliss Steam Engine Company in 1857, and by 1864 Corliss had purchased full ownership.

engine sold that same year for $8,600 without the boiler, and its success quickly led to several more sales. By the time of the final patent award in 1849, they were already building a new and expanded factory. The company was renamed the Corliss Steam Engine Company in 1857, and by 1864 Corliss had purchased full ownership.

The standard American high-pressure steam engine of the 1840s was based on the slide valve. There is a steam chest along one side of the cylinder: as the slide valve moves back and forth, it alternately admits and vents steam on both sides of the piston. After the success of the engine in river steamboats, it spread rapidly throughout industry, freeing mills and forges from the dependency on waterpower. Even in waterpower-rich New England, rising power demands and winter production losses forced the shift to steam. The Lowell Locks and Canals Company acquired its first steam engine in 1850 and had thirty-nine by 1870.

But as the stationary steam engine became the factory power source of choice, its gross deficiencies became the more apparent. For one thing, standard engines were prodigal consumers of coal. Fuel was usually the biggest factory expense after personnel. Just as important, the energy output from most engines was very irregular. In small shops, that was rarely an issue, but in a large textile mill, where high gearing often ran looms at extreme speeds, power variations were amplified to violent effect. Even with steady power, if several big looms went down at the same time, the drop in power load could cause the other looms to spin at destructive speeds. In a big iron rolling mill, the sheer weight of the machinery made variations in power especially damaging. A skilled operator could throttle steam up or down, but the inherent lag between the action and its full effect made it hard to prevent major plant disruptions.

Corliss's first patent addressed both fuel consumption and speed regulation as related problems. The operations of a standard slide valve exposed each end of the steam chest to alternate doses of fresh and expanded steam. The temperature differentials were wide enough that much of the heat in the fresh steam was spent on rewarming the steam chest. Corliss's first innovation was to completely separate the intake and exhaust operations to minimize the need to reheat the apparatus on each cycle.

The second innovation was to rethink the throttle. In the slide valve engine, the throttle limited the steam entering the piston cylinder from the steam chest while venting any excessâthus wasting good steam. Instead, Corliss regulated the engine with an automatic variable cutoff valve. To reduce or increase power, Corliss reduced or lengthened the period of the valve that admitted steam directly into the cylinder. Since just the right amount of steam was delivered, none had to be vented, so energy waste was greatly reduced. The regulation of the valve cycle was performed by the traditional spinning-ball governor. As the engine changed speeds, centrifugal force would change the plane of the balls' rotation, and an apparatus connecting the governor to the valves would modify the valve settings proportionately. An important fillip was that as the balls approached horizontal, the valve connection was droppedâin the words of the patent, the valve was “liberated”âso it would shut almost instantaneously. (A clever latch arrangement automatically reconnected a closed liberated valve, while a shock absorber prevented any damage from too hard a closing.) The inventions, moreover, were adaptable to any type of steam engine.

Modern analyses show that Corliss's valves and valve management systems improved fuel efficiency by about 30 percent. Since Corliss's early sales were almost all to replace older engines, the savings were usually 50 percent or more. British observers were inclined to mock the awkward-looking rods on the outside of the machine

bj

but were converted by its performance at the Paris Exposition of 1867, where it won the gold medal. A British engineer wrote of the Paris engine that it was “refined, elegant, most effective and judicious . . . spares steam to the utmost but develops what it uses to most effect.” The governor was “sensitive to the most delicate changes of speed, and feels the slightest demand upon the engine for more or less work and steady speed.” In sum, the review concluded, “everywhere tells of wise forethought, judicious proportion, sound execution, and exquisite contrivance.”

bj

but were converted by its performance at the Paris Exposition of 1867, where it won the gold medal. A British engineer wrote of the Paris engine that it was “refined, elegant, most effective and judicious . . . spares steam to the utmost but develops what it uses to most effect.” The governor was “sensitive to the most delicate changes of speed, and feels the slightest demand upon the engine for more or less work and steady speed.” In sum, the review concluded, “everywhere tells of wise forethought, judicious proportion, sound execution, and exquisite contrivance.”

Â

Corliss's first innovation was to save steam by separating the entry and exhaust valves on each side of the piston. (A conventional slide valve both admitted and expelled steam leading to wide temperature variation both at the valve and within the steam chest, so steam was wasted on reheating engine parts.) The exterior drawings show how the Corliss wristplate and the valve rods manage the valve actions, while the interior drawings show the separation of the steam intake and expulsion actions. The second innovation was that the intake period could be precisely timed to accommodate shifting power requirements. Conventional engines tuned power through a throttle that slowed the rate of steam admission, necessarily wasting excess steam. The drawing on the next page illustrates the Corliss timing mechanism.

Â

The power engineer could set a maximum speed for the engine rotation. Speed would be measured by the rotating flyball governor in the inset. When the governor reached the preset speed, it triggered the valve regulator, and a drop lever instantly shut the intake valve. If a number of looms went down in a large mill, the Corliss would instantly reduce power to the point where they continued to operate at a constant speed, and would make a comparable adjustment as the failed looms were brought back on line.

Other books

Ambrosia by Erin Noelle

All Night Awake by Sarah A. Hoyt

Tras el incierto Horizonte by Frederik Pohl

The Incident at Montebello by P. A. Moed

Chanelle Hayes - Baring My Heart by Hayes, Chanelle

Conceived in Liberty by Murray N. Rothbard

Mama Said by Byrne, Wendy

A Precious Jewel by Mary Balogh

Revenger 9780575090569 by Alastair Reynolds

Courting Jealousy by Kimberly Dean