With Love and Quiches (5 page)

Read With Love and Quiches Online

Authors: Susan Axelrod

Bonne Femme was not yet quite a full-time enterprise for either Jill or me, and I still had time to cook for friends. One evening, Irwin and I had our across-the-street neighbors and their children over for dinner. During the meal, we were discussing my little business, and I became the inadvertent entertainment, the butt of jokes and good-natured laughter, when I explained where we were buying our supplies.

“How about wholesale?” my neighbor said. “Wholesale?” I said. It had never occurred to us that we could buy such small amounts at wholesale. But we could, my neighbor told me, and we did! The very next day, Jill and I pulled out the Yellow Pages and found a ton of local suppliers.

One was a fresh egg supplier who would break the eggs for us and sell them to us by the pail. He would deliver them, too. It amazed me to learn that a case of extra large eggs (thirty dozen) would weigh

exactly

forty pounds every time! Only problem was that we were sure he had a habit of putting his finger on the scale, so I suspect that we rarely got what we had actually paid for.

I found myself with an enterprise that seemed to have a will and a pull of its own. We were getting busier, and needed help. By now we had a few friends and neighbors coming in on occasion, some for two hours every Tuesday and Thursday, others maybe for one hour every Monday and Wednesday. They rolled dough, grated cheese, packed the frozen quiches, and tasks like that. I don’t even remember whether we paid them at first. But Jill and I still did all the mixing. The extra hands gave us some relief, but I couldn’t help noticing that my kitchen was feeling more cramped by the day.

In the first year of Bonne Femme, I learned loud and clear that I wasn’t going to stop—not until what we had started became real. A spark had been lit inside me. We already had our tentative market identified, so, to my thinking, all we needed to do was reach

more of it.

But to do that we needed more product, along with more storage space and better equipment. Little by little we began to segue from my kitchen into my garage, our very first move. My kitchen, by now a complete wreck, must’ve been relieved.

We had the garage fitted out with 220-volt outlets and bought our first commercial equipment. We found a local restaurant equipment supply wholesaler who sold us a life-altering commercial-grade freezer that was three times the size of our current one, a huge commercial fridge, and a miraculous freestanding double convection oven with six shelves in each. We could bake up to thirty-six pies at a time in each one! No more toy building blocks for us. No more ferrying batter between houses, either. We now had room to buy a few bakers’ racks, several dozen bun pans, and some other wonderful kitchen aids. Our work table was made up of two sawhorses and a huge plywood slab, and we felt we were luxuriating in space!

In the months after our move to the garage, we gathered a few more customers, widening our sales area by a few slightly larger concentric circles. How fast we could grow was limited because I was still the only delivery guy. I had a little freezer truck going in the trunk of my car. Did you know that newspaper is the quintessential insulator? It was my secret to keeping the raw quiches from melting and the pecan pies from wilting.

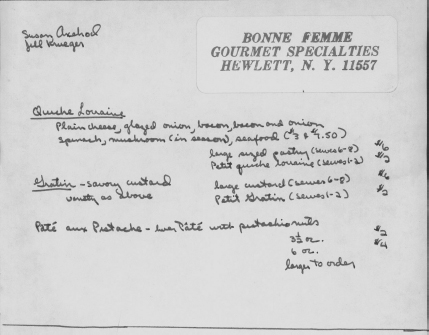

Bonne Femme’s customer count grew to about twenty-five. We concentrated on the pubs, yogurt shops, and sandwich shops: no place too fancy because we didn’t yet have that much to sell. We were preparing maybe 150 products a week, but at an average of about $3 each, it didn’t amount to much. Notice that we did not list any weights on our very first price list:

Still clueless, we continued to operate in the Keystone Kops tradition: two steps forward, three steps back. Nevertheless, the garage was our first mini-factory, and we started to think of our little enterprise as more of a business and less of a hobby.

We met up with a dealer in secondhand bakery equipment who served as somewhat of a mentor to us. The owner of another local bakery right in our hometown of Hewlett introduced us to him. That bakery—another place where we learned a great deal—is still there to this day and has been thriving in a world where most independent bakeries are a dying breed.

This dealer introduced us to the Comtec Pie Press. With the press of a button on this miracle laborsaving machine, we could stamp our dough into the pie pan, fluted border and all, in two seconds! Prior to that, we often felt as if we were spending our entire lives rolling dough by hand. We used to stand side by side in front of our worktable and have rolling contests set to music—Frank Sinatra, Tony Bennett, Ray Charles, and some rock and roll—to help pace us and get the work

done a little faster. The pie press was revolutionary for us. The dealer also sold us two twenty-quart mixers, and so,

finally

, we graduated from our original kitchen Mix Masters (with ten times the capacity). Every single thing he sold us was secondhand and reconditioned, but it all worked just as if it were brand-new. He also taught us a lot about the bakery business, pointing out where we could go to find potential new customers and for better sources of supplies, as well as encouraging us to raise prices a bit.

What we had going was still embarrassingly rudimentary, however. We

did

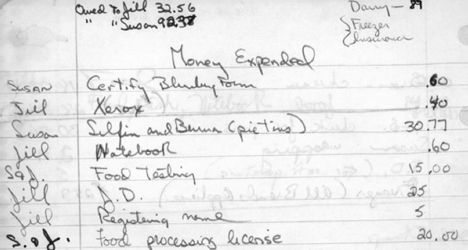

start keeping records several months in, but they were just running lists that we jotted down on whatever paper we could find.

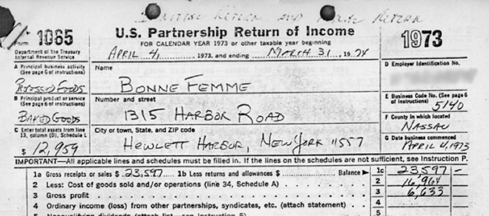

We called our receivables “owables,” our term for “those who owed us”! Of course, we had no “payables” because we had no credit and had to pay for everything up front. Nevertheless, we were coming up on the end of our first year in business with a grand total of $23,597 in gross sales! On our tax return we showed our cost of labor for the year as being $222, so we must have paid somebody for something, but for what, I can’t recall. We were still unaware that our own labor even counted; we were just feeling our way.

Up to that point, even with Jill’s and my discounted labor of $0 per hour, we still had no profit. Businesses exist to make a profit, not to fill up the day. We had yet to figure out that simple tenet. (About that time we hired a young accountant fresh out of school. Ours was considered a “shoebox business,” one in which all receipts, sales, purchases, employee records, notes, etc. were kept on scraps of paper in a small box that we would hand over to him at the end of the year. It was our hope that he would make some sense out of it all.)

Nevertheless, some patterns began to emerge. At first Jill and I generally shopped, baked, and developed new products together, but little by little, Jill became more the inside person holding down the fort, and I became more the outside sales “expert.” By now we were paying our friends for their time, and Jill did the payroll each week. As she confided to me recently, at that time this was an agonizing learning curve.

Still

we continued to grow, and the garage began to get really crowded. We were in the second half of our first year, a transitional period for us.

At that point we were still selling only quiches and pecan pie in about equal amounts, but we were definitely ready to add to our repertoire. We started by adding other desserts. We would try out our recipes on our friends during the weekends to see which ones they liked best. This was a lesson in learning from your customers! We started producing a delicious cheesecake in a nine-inch pie pan because that was still the

only

pan size we had, and then we added a few apple slices to make

an apple cheesecake. One day we dropped an entire pail of cheesecake batter on the floor, but we had all these lovely apples prepared already, which prompted the accidental birth of our Swiss Apple Tart. There was just enough cheesecake batter left in which to bathe the apples, so—

voil

à—our third product! I assume that we added a chocolate dessert shortly after this, too, because there was still chocolate on the ceiling in my kitchen for the next fifteen years until I got around to redoing it.

Keystone Kops antics kept up all throughout the early days. First, we experienced what we termed our great Pecan Pie Disaster. Classic pecan pie filling is extremely dense, and if there is the slightest flaw in the crust, the batter will seep through during baking and the crust will rise to the surface, just under the pecans. The result is upside-down pecan pies—not exactly salable. (Even we knew that!) As usual, we found this out the hard way. Once was bad enough, but when it happened a

second

time, we needed to do something about it. We laid out all thirty of the ruined pies on the table and started picking off the pecans to see what was just under the surface. To our dismay, it was the crust, not the filling. We started absentmindedly eating the caramelized pecans, one by one, until we had eaten

at least two pounds

each. Not a very good thing to have done. We didn’t quite get sick, but we examined the prepared crusts a lot more carefully after that, closing any gaps before filling them with batter. Unfortunately a few errant pies slipped through, prompting our very first customer complaints.

Then there was the Pâté Disaster. In our desire to round out our offerings, we started producing a very elegant liver pâté for our very first account, the Windmill supermarket. But we had only a

bakery

license from the state; to make products with meat, you need to be USDA inspected. Our bakery inspector went crazy when she came in for a visit and saw the pâté in the fridge, and we went running to the Windmill to clear it all off the shelf. The inspector gave us a pass, but we should’ve known better. We

did

use bacon in the quiche, but after the pâté fiasco, we were careful to keep it to less than 3 percent of the total weight so that the USDA requirement wouldn’t apply to us.

We still had no scales; everything was poured by eye. I suspect, now, that we always gave more, not less, so maybe that’s one of the places that our hoped-for profits went. It should have been easy to figure out by the sad lack of growth in our bank account. Our friends still kept coming to help us out as we grew, and our kids still had to show up after school to help out. It was about then that my housekeeper, Bridget, my regal sidekick from my dinner party days, started spending a few hours a day in the garage with us. She was Bonne Femme’s first real employee, even if she was only commuting from inside the house. She was our efficiency expert and would point out obvious ways to speed up our methods, making us feel somewhat silly.

After our first year in business, things started to accelerate at an almost dizzying pace. Our quaint little kitchen business, which hadn’t even been my idea in the first place, was taking on a life of its own. For me, a former bored housewife, the process of growing into something big was exhilarating.

One of the most important steps in the process was meeting Marvin Paige. He was a well-regarded New York City restaurateur, and the brother of my college roommate was kind enough to introduce us. Marvin looked just like Santa Claus, had an outsized personality, and was very giving. He didn’t know me from a hole in the wall, but he had the patience to spend countless hours on the phone teaching me all about the restaurant business before we even met in person. Meeting him changed everything!