The Case for Mars (12 page)

The more closely we examined it, the better this new mission architecture looked. So, we proceeded to elaborate the required subsystems and vehicle designs. I focused on the chemistry of Mars propellant synthesis. The dominant school working in this area in 1990 was investigating a novel process for splitting carbon dioxide (CO

2

) into carbon monoxide (CO) and oxygen (O

2

), which could then be burned together as rocket propellant. The only raw material requir

ed—CO

2

—was free as air on Mars.

There were many disadvantages however. The process was relatively unproved, and, at the scale of production needed to support a manned Mars mission, it would require the use of tens of thousands of small, brittle ceramic tubes with high-temperature (~ 1,000° Centigrade) seals at each end of each tube to make a reactor. In addition, the carbon monoxide/oxygen bipropellant it produced was a poor quality rocket propellant with a specific impulse of only about 270 seconds. (“Specific impulse,” or “Isp” is the number of seconds a pound of rocket propellant can be made to produce a pound of thrust. The higher that number is, the better. German V-2 rocket engines used in World War II had an Isp of about 230 seconds; current-day Pratt and Whitney RL-10 engines burning hydrogen and oxygen have an Isp of 450 seconds; and a nuclear rocket engine using hydrogen propellant could have an Isp of 900 seconds.) The low performance of the CO/O

2

propellant mixture would mean that very large and heavy propellant tanks would need to be carried to Mars to hold the required propellant for the return flight. Also, the carbon monoxide/oxygen propellant combination burns with a very high flame temperature, and no engine is yet available that can operate with it. The development of such an engine would be a significant cost and schedule risk.

An alternative was to make a methane/oxygen (CH

4

/O

2

) propellant mixture. The advantage here was that methane/oxygen is the highest-performing (Isp = 380 seconds) chemical combination that can be readily stored for long stretches on the surface of Mars. While no flight-rated CH

4

/O

2

engines were available, the combination had been run successfully in RL-10 engines on the test stand, and the engines’ makers, Pratt and Whitney, had published assessments showing that the modification of the RL-10 to CH

4

/O

2

operation would be a relatively straightforward and low-cost program. But there’s a problem: you need hydrogen (the H in CH

4

) to make methane, and it’s not easy to come by on Mars. So where on Mars do you get the hydrogen? In 1976, Professor Robert Ash, now of Old Dominion University, and some JPL collaborators published a paper laying out some extremely simple, robust, and well established (Gaslight Era, to be p

recise) chemical engineering processes that would produce a methane/oxygen bipropellant on Mars, provided a source of water (H

2

O) could be found. But that was the sticking point—water. Mining water out of Martian permafrost is not really a credible option for an initial automated mission, and condensing it out of the extremely arid Martian atmosphere would be extremely difficult. So Ash had moved on to examining CO/O

2

production. But in looking at Ash’s proposal, I realized that the only problem his group really had was excessive purism—an insistence that

all

of the propellant come from Mars. But in fact, the hydrogen required to support their chemical process was just 5 percent by weight of the total propellant produced. So why not just bring that relatively small amount of hydrogen from Earth? I checked with Martin’s cryogenic (super-cold) fluid storage experts, and they were unanimous in their opinion that storing the 6 tonnes or so of hydrogen needed during an eight-month outbound trip from Earth to Mars was nothing they couldn’t handle, provided we started out with about 15 percent extra to cover evaporation (“boiloff”) losses in transit (once on Mars any hydrogen boiloff could be sent straight into the methane reactor and thus would not be lost). Conceptually, this solved the problem of how to produce a viable rocket propellant combination on Mars.

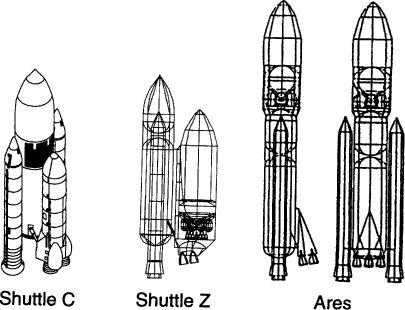

Meanwhile, with the help of Sid Early, a Martin launch vehicle trajectory analyst, Baker redesigned the Shuttle Z into the “Ares,” a booster optimized not to lift payloads to low Earth orbit, but to throw them directly into interplanetary space. (See

Figure 3.1

.) He also came up with a scheme for using the burnt-out upper stage of the Ares as a counterweight on the end of a rotating tether to create artificial gravity in the crew habitat during the outbound trip to Mars. Tether-generated artificial gravity schemes were nothing new, but our plan was much more robust than others as the object at the far end of the tether from the crew was not mission critical. In more conventional missions, because of the huge mass of the outbound spaceship, tether-generated artificial gravity had to be created by dividing the ship and putting vital components, such as chemical propulsion stages needed for Earth return, at the far end of the tether. If such a tether should snag when the time came to reel it in, the mi

ssion would be lost. In contrast, the tether on our mission would never have to be reeled in. Rather, when the hab reached Mars, it would simply be released or cut by the firing of an explosive bolt. This was a major reduction in mission risk, and a strong illustration of one of the derivative advantages of our mission architecture.

FIGURE 3.1

Booster evolution from Shuttle C to Shuttle Z to the Ares

.

So it went. Baker proposed using two space station modules as the basis for the hab, since those presumably would be off-the-shelf items by the date of our mission. Space station modules are long and thin, like an airplane fuselage, designed that way because they have to fit inside the five-meter-diameter space shuttle payload bay. I pointed out that the real development work associated with the space station module revolved around its life-support and other interior systems, not the manufacture of its hull. A fatter “tuna-can” shape that took better advantage of the 10-meter-diameter fairing available on the Ares offered much better possibilities for a “human friendly” design for a long duration habitat than a pair of space station modules, I argued, and would be considerably lighter to boot. After playing around with various sketch designs of habitat interiors, Baker satisfied himself that this indeed was the case and so we chose the tuna-can. The

tuna-can hab fit beautifully and symmetrically upon the dead center of one of Bill Willcokson’s folding aerobrake designs. The hab would nestle comfortably within a folded aerobrake that fit inside the Ares’ fairing. Since we wanted a set of vehicles that could be used to accomplish lunar missions as well as Mars (as a sort of side benefit, not as an intermediate step), we decided to split the ERV’s propulsion into two stages. The upper stage by itself would have just the right propellant load to allow a directturn to Earth from the surface of the Moon, while the two stages together could drive the ERV home from Mars. Because the upper stage by itself was much smaller than the lower stage, an Ares could be used to deliver a fully fueled ERV to the lunar surface (making rocket propellant on the Moon is possible but unlikely for an initial mission, as it requires breaking down rocks). So designed, the Ares, the hab, the two-stage ERV and the aerobrake module provided a compact (and therefore low-cost) set of elements that could be mixed and matched to accomplish both the lunar and Mars objectives of the Space Exploration Initiative. With the help of CAD (computer assisted design) engineer Bob Spencer and company artist Robert Murray (that’s right, artist: a good engineering artist can make extraordinary contributions to a design effort by forcing you to think and explain how

this

fits into

that

, and how someone could get from

here

to

there

), all the sketch designs were fleshed out into three-dimensional engineering drawings.

On grounds of minimalism, Baker preferred a crew of three; I wanted five. We worked through the mission logistics and it turned out we had enough payload delivery capability to support a crew of four. So four it was. (The choice was that simple. For reasons explained in a later chapter, however, I have since become convinced that four is just the right number to bring on an initial human Mars expedition.)

One day toward the end of our design work, I walked into Baker’s office and sat down on his desk. “We need a name for the plan,” I said, “something that captures its essence. We’re going to Mars directly, both programmatically, in terms of avoiding orbital and lunar development, and physically, in terms of doing the mission by direct throw of the booster outbound, and direct return from the surface inbound. So I was thinking of something like the ‘Direct Plan,’

or the ‘Direct Mars’ approach.” Baker looked at me and said, “Okay . . . how about . . . ‘Mars Direct?’” He only had to say it once. The plan had a name.

Upon completion, we presented the plan to the scenario development team and to a management group for scrutiny. Ben Clark wrote out several pages of tough questions and criticisms about the plan that we had to, and did, answer successfully in writing. Al Schallenmuller, the Martin Marietta Civil Space vice president, was very excited about the plan. Everything needed to accomplish our mission was near-term and relatively simple. Based on his Skunkworks experience, he agreed with my assessment that the Mars Direct plan held the potential for

humans to Mars within ten years.

He decided to fly us down to Marshall Space Flight Center, in Huntsville, Alabama, to present the plan to NASA.

Neither Baker nor I expected the briefing at Marshall to be well received. Marshall is one of the most conservative of the NASA centers, and it seemed unlikely that any Marshall audience would be favorably inclined towards an idea as radical as Mars Direct. Regionalism would be a real barrier too, acting to greatly reinforce the “not invented here” factor. As I predicted to Baker at the time, only half in jest, the Marshall response was likely to be, “My daddy didn’t fly Mars missions that way, and his daddy didn’t fly Mars missions that way, and we don’t need no damnyankees coming down here to tell us how to fly Mars missions.”

I couldn’t have been more wrong. Baker and I pitched the mission plan jointly, tag team style. The response was electric. The Marshall SEI planning group was conservative, and, precisely for that reason, became very excited about Direct. For months they had been deluged with grandiose plans for the on-orbit assembly of huge interplanetary spaceships, all of which they regarded as complete hogwash. When we explained how a manned Mars mission could be accomplished with two launches of a Saturn V equivalent booster, the eyes of Apollo program veterans sitting in the room began to light up: “Hey, this is something that we could actually do!” Gene Austin, the head of the Marshall SEI organization, took Baker and me into his office to talk about the plan for two hours (unheard of), first exploring the concept, and then giving us advice as to how to present the

plan at Johnson Space Center and elsewhere.

The Marshall briefing took place on April 20, 1990. In the following weeks we visited every major NASA center involved in SEI with similar presentations, and everywhere we went we lit fires. On Memorial Day, I was given the opportunity to present the closing plenary talk at the national conference of the National Space Society in Anaheim. This was the first public presentation of Mars Direct. I received a

standing ovation.

A week later, Baker and I presented the plan to the “Case for Mars” conference (the triennial gathering of the “Mars Underground,” more about which to come) in Boulder, and basically took the place over. The next day, under the byline of its veteran science reporter David Chandler, the

Boston Globe

ran a front-page story, “New Mars Plan Proposed,” that was carried by wire and printed in hundreds of other papers as well. Mars Direct was out of the box.

As the summer wore on, Baker and I, singly or together, continued to make presentations at open conferences and NASA briefings. We published a detailed description of the mission as a feature magazine article in

Aerospace America

, the industry monthly, as well. Everywhere we went we made converts, but a counterattack was in the works. Powerful forces within NASA linked to the Space Station program were not happy at all about Mars Direct. Since we didn’t use the Station or even its (to be created) heritage of on-orbit assembly techniques, we were, in their view, “de-justifying” their program. People in NASA who had been friendly to Mars Direct were told to keep their distance. This slowed us down. Some (but not all) factions in the advanced propulsion community were also hostile. They felt that Mars Direct was “de-justifying” their programs as well, and argued for mission requirements that only their systems could meet. Refuting the need for these requirements slowed us down some more. What had begun as an intellectual blitzkrieg began turning into trench warfare.