Power Hungry (31 page)

Authors: Robert Bryce

Sources

: Donald Sadoway, “Power Storage: Batteries and Beyond,” February 12, 2009; John Newman, University of California, Berkeley, personal communication with author, January 16, 2009; David J.C. MacKay,

Sustainable EnergyâWithout the Hot Air

(Cambridge: UIT Cambridge, 2009) (online at

http://www.inference.phy.cam.ac.uk/sustainable/book/tex/cft.pdf

), 284.

: Donald Sadoway, “Power Storage: Batteries and Beyond,” February 12, 2009; John Newman, University of California, Berkeley, personal communication with author, January 16, 2009; David J.C. MacKay,

Sustainable EnergyâWithout the Hot Air

(Cambridge: UIT Cambridge, 2009) (online at

http://www.inference.phy.cam.ac.uk/sustainable/book/tex/cft.pdf

), 284.

Given that batteries hold such small amounts of energy, designers of electric vehicles must, in effect, build their cars around the bulk and weight of the battery pack. For instance, on the Tesla Roadster, arguably the most famous electric car now available, the battery pack weighs 992 pounds, or slightly more than one-third of the curb weight of the vehicle, which tips the scales at 2,723 pounds.

22

22

In 2009, Bill Reinert, one of the lead designers of the Toyota Prius, told me that existing battery technology simply “does not provide the cost, durability and energy storage attributes that allow for the development of mass-market products. We can get around some of these issues with niche products, or schemes like battery leasing, or subsidizing the products, but none of these are solutions for the mass market.” And while Toyota is planning to develop an all-electric car, he said, the company is

“looking at sales volumes of thousands, not millions. To produce an electric vehicle that's truly intended for a mass market, a replacement for your current gasoline car, we're going to need a battery chemistry that isn't currently available.”

23

“looking at sales volumes of thousands, not millions. To produce an electric vehicle that's truly intended for a mass market, a replacement for your current gasoline car, we're going to need a battery chemistry that isn't currently available.”

23

Reinert's view was reinforced by a report on energy storage that was released by the U.S. Department of Energy's Office of Vehicle Technologies in early 2009. The report concludes that despite the enormous investments being made in plug-in hybrid-electric vehicles and lithium-ion batteries, four key barriers stand in the way of their commercialization: cost, performance, abuse tolerance, and life. The DOE's summary deserves to be read in its entirety:

Cost: The current cost of Li-based [lithium-based] batteries (the most promising chemistry) is approximately a factor of three to five too high on a kWh [kilowatt-hour] basis. The main cost drivers being addressed are the high cost of raw materials and materials processing, the cost of cell and module packaging, and manufacturing costs.

Performance: The performance barriers include the need for much higher energy densities to meet the volume/weight requirements, especially for the 40-mile system, and to reduce the number of cells in the battery (thus reducing system cost).

Abuse Tolerance: Many Li batteries are not intrinsically tolerant to abusive conditions such as a short circuit (including an internal short circuit), overcharge, over-discharge, crush, or exposure to fire and/or other high temperature environments. The use of Li chemistry in these larger (energy) batteries increases the urgency to address these issues.

Life: The ability to attain a 15-year life, or 300,000 HEV [hybrid-electric vehicle] cycles, or 5,000 EV [electric vehicle] cycles are unproven and are anticipated to be difficult. Specifically, the impact of combined EV/HEV cycling on battery life is unknown and extended time at high state of charge is predicted to limit battery life.

24

24

Of course, the DOE's grim prognosis hasn't prevented the media from gushing over all-electrics. Consider this quote from the

Los Angeles Times

: “The electric automobile will quickly and easily take precedence over all other” types of motor vehicles. That declaration was published on

May 19, 1901, in a story headlined: “Edison's New Storage Battery.” “If the claims which Mr. Edison makes for his new battery be not overstated, there is not much doubt that it will make a fortune for somebody,” the article said.

25

Los Angeles Times

: “The electric automobile will quickly and easily take precedence over all other” types of motor vehicles. That declaration was published on

May 19, 1901, in a story headlined: “Edison's New Storage Battery.” “If the claims which Mr. Edison makes for his new battery be not overstated, there is not much doubt that it will make a fortune for somebody,” the article said.

25

Today's electric carsâonce againâmay be on the verge of yet another spectacular breakthrough. But, just for fun, let's take a quick drive past a few newspaper stories:

⢠1911: The

New York Times

declares that the electric car “has long been recognized as the ideal solution” because it “is cleaner and quieter” and “much more economical.”

26

New York Times

declares that the electric car “has long been recognized as the ideal solution” because it “is cleaner and quieter” and “much more economical.”

26

⢠1915: The

Washington Post

writes that “prices on electric cars will continue to drop until they are within reach of the average family.”

27

Washington Post

writes that “prices on electric cars will continue to drop until they are within reach of the average family.”

27

⢠1959: The

New York Times

reports that the “Old electric may be the car of tomorrow.” The story said that electric cars were making a comeback because “gasoline is expensive today, principally because it is so heavily taxed, while electricity is far cheaper” than it was back in the 1920s.

28

New York Times

reports that the “Old electric may be the car of tomorrow.” The story said that electric cars were making a comeback because “gasoline is expensive today, principally because it is so heavily taxed, while electricity is far cheaper” than it was back in the 1920s.

28

⢠1967: The

Los Angeles Times

says that American Motors Corporation is on the verge of producing an electric car, the Amitron, to be powered by lithium batteries capable of holding 330 watt-hours per kilogram. (That's more than two times as much as the energy density of modern lithium-ion batteries.) Backers of the Amitron said, “We don't see a major obstacle in technology. It's just a matter of time.”

29

Los Angeles Times

says that American Motors Corporation is on the verge of producing an electric car, the Amitron, to be powered by lithium batteries capable of holding 330 watt-hours per kilogram. (That's more than two times as much as the energy density of modern lithium-ion batteries.) Backers of the Amitron said, “We don't see a major obstacle in technology. It's just a matter of time.”

29

⢠1979: The

Washington Post

reports that General Motors has found “a breakthrough in batteries” that “now makes electric cars commercially practical.” The new zinc-nickel oxide batteries will provide the “100-mile range that General Motors executives believe is necessary to successfully sell electric vehicles to the public.”

30

Washington Post

reports that General Motors has found “a breakthrough in batteries” that “now makes electric cars commercially practical.” The new zinc-nickel oxide batteries will provide the “100-mile range that General Motors executives believe is necessary to successfully sell electric vehicles to the public.”

30

⢠1980: In an opinion piece, the

Washington Post

avers that “practical electric cars can be built in the near future.” By 2000, the average family would own cars, predicted the

Post

, “tailored for the purpose for which they are most often used.” It went on to say that “in this new kind of car fleet, the electric vehicle could pay a big roleâespecially as delivery trucks and two-passenger urban commuter cars.

With an aggressive production effort, they might save 1 million barrels of oil a day by the turn of the century.”

31

Washington Post

avers that “practical electric cars can be built in the near future.” By 2000, the average family would own cars, predicted the

Post

, “tailored for the purpose for which they are most often used.” It went on to say that “in this new kind of car fleet, the electric vehicle could pay a big roleâespecially as delivery trucks and two-passenger urban commuter cars.

With an aggressive production effort, they might save 1 million barrels of oil a day by the turn of the century.”

31

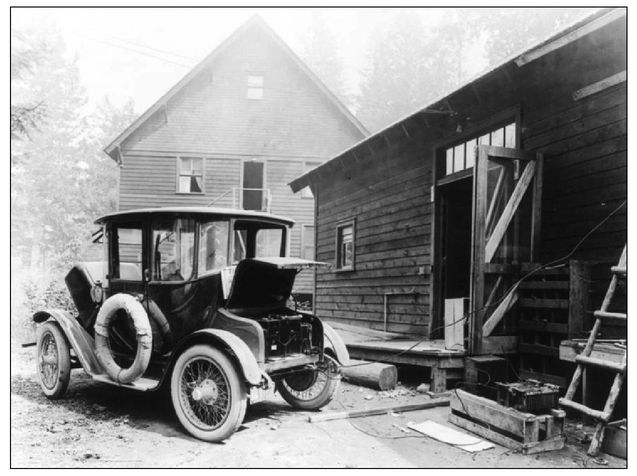

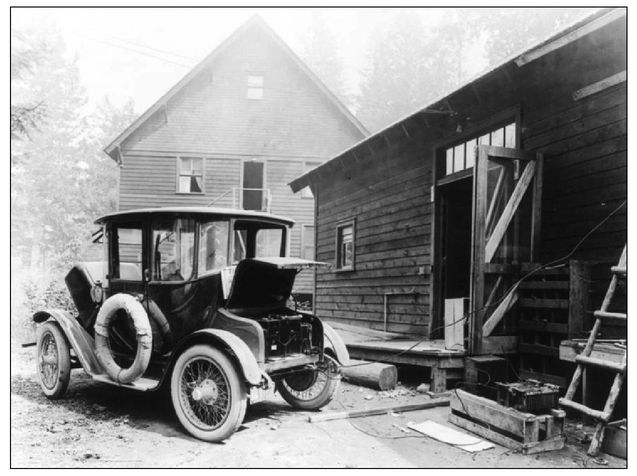

PHOTO 6 What's old is new again. In 1919, this Detroit Electric automobile stopped for a charge.

Source

: Library of Congress, LC-USZ62-46285.

: Library of Congress, LC-USZ62-46285.

But ignore the headlines of the past and consider the path of Tesla Motors, the outfit named for Nicola Tesla, the electricity pioneer who once worked with Thomas Edison and who went on to invent the induction electric motor. Although Tesla has been dead since 1943, the company named for him is producing the Roadster, which is snagging rave reviews. One writer called it “a frantic road dart on twisty roads.”

32

In mid-2009, London's

Daily Telegraph

called the car “one of the stars of this year's London Motorexpo.” The reviewer for the

Telegraph

praised the car's acceleration, saying that when one stomps on the accelerator, “the result is little short of astonishing. The Tesla belts away with the seamless surge of a catapult launch.”

33

But given its high price, the Tesla is hardly a catapult for the common man,

34

and like its predecessors from

a century ago, it faces the familiar issues of charging time, weight, and range. The car has a claimed range of 220 miles, and fully recharging the car's batteries takes at least four hours.

35

32

In mid-2009, London's

Daily Telegraph

called the car “one of the stars of this year's London Motorexpo.” The reviewer for the

Telegraph

praised the car's acceleration, saying that when one stomps on the accelerator, “the result is little short of astonishing. The Tesla belts away with the seamless surge of a catapult launch.”

33

But given its high price, the Tesla is hardly a catapult for the common man,

34

and like its predecessors from

a century ago, it faces the familiar issues of charging time, weight, and range. The car has a claimed range of 220 miles, and fully recharging the car's batteries takes at least four hours.

35

That point leads to another critical challenge for all-electric cars: long refueling times. All energy sources are limited in how fast they can release energy and how fast they can be replenished. With batteries, the refiller is the killer, particularly when compared with the time needed to refuel with good old conventional gasoline.

In May 2009, with the fuel gauge on my 2000 Honda Odyssey minivan showing empty, I pulled into a Texaco station to fill up. Total elapsed time from inserting the nozzle into my tank until the automatic shut-off valve clicked off, signaling full: 1 minute and 59 secondsâabout the time that it takes Michael Phelps to swim the 200-meter butterfly.

36

In less than 2 minutes, I pumped about 18.5 gallons of gasoline into the vehicle. That's the energy equivalent of more than 600 kilowatt-hours of electricity, or about eleven times as many kilowatt-hours as are contained in the Tesla Roadster's battery pack. Put another way, I loaded about eleven times as much energy as what is contained in the batteries in the Teslaâand I did it in 1/120th of the time that is needed to recharge the Tesla's battery system. (Recall that recharging the 53-kilowatt-hour battery pack in the Tesla takes about 4 hours, or 240 minutes.) The total cost of refueling my Honda van: $44.32.

36

In less than 2 minutes, I pumped about 18.5 gallons of gasoline into the vehicle. That's the energy equivalent of more than 600 kilowatt-hours of electricity, or about eleven times as many kilowatt-hours as are contained in the Tesla Roadster's battery pack. Put another way, I loaded about eleven times as much energy as what is contained in the batteries in the Teslaâand I did it in 1/120th of the time that is needed to recharge the Tesla's battery system. (Recall that recharging the 53-kilowatt-hour battery pack in the Tesla takes about 4 hours, or 240 minutes.) The total cost of refueling my Honda van: $44.32.

Now, were I to buy 53 kilowatt-hours of electricity from the local utility, at an average cost of $0.10 per kWh, the total cost of the fuel would only be about $5.30âfar less than the $44 I paid to refill my minivan. But then, my van doesn't need recharging every nightâwhich leads to another key issue with all-electric or plug-in hybrid vehicles: the lack of recharging locations. According to a June 2009 report by the Government Accountability Office, “about 40% of consumers do not have access to an outlet near their vehicle at home.” The report goes on to say that consumers who don't have access to electric power near their cars would need “public charging infrastructure, which manufacturers and others told us could be installed at a relatively low cost of perhaps a few thousand dollars for a new charging box.”

37

37

Despite the myriad challenges facing the electric car business, Congress and the Obama administration are hurling billions of dollars at it.

Among the most notable recipients of the government's largesse: Fisker Automotive. In September 2009, Fisker received a $529 million loan from the U.S. government to help finance its startup costs. One of Fisker's main financial backers is the venture capital firm Kleiner Perkins Caufield & Byers, a Silicon Valley firm where Al Gore is a partner.

38

Among the most notable recipients of the government's largesse: Fisker Automotive. In September 2009, Fisker received a $529 million loan from the U.S. government to help finance its startup costs. One of Fisker's main financial backers is the venture capital firm Kleiner Perkins Caufield & Byers, a Silicon Valley firm where Al Gore is a partner.

38

Fisker wasn't alone. Nissan got a $1.6 billion loan, and Tesla Motors got a $465 million loan.

39

Two Phoenix-based companies, Electric Transportation Engineering and ECOtality, were given $99.8 million in federal stimulus money to help roll out an electric vehicle pilot program in several U.S. cities.

40

Johnson Controls, one of America's biggest battery makers, got a federal grant for $299.2 million to help it build batteries for electric and hybrid cars. General Motors got $105.9 million to help it produce battery packs for the Chevy Volt. In all, about fifty different entities were given federal grants (all provided by the stimulus package passed by Congress) that totaled some $2.4 billion as part of an “electric drive vehicle battery and component manufacturing initiative.”

41

39

Two Phoenix-based companies, Electric Transportation Engineering and ECOtality, were given $99.8 million in federal stimulus money to help roll out an electric vehicle pilot program in several U.S. cities.

40

Johnson Controls, one of America's biggest battery makers, got a federal grant for $299.2 million to help it build batteries for electric and hybrid cars. General Motors got $105.9 million to help it produce battery packs for the Chevy Volt. In all, about fifty different entities were given federal grants (all provided by the stimulus package passed by Congress) that totaled some $2.4 billion as part of an “electric drive vehicle battery and component manufacturing initiative.”

41

In announcing the initiative, President Obama said that the grants were “planting the seeds of progress for our country, and good-paying, private-sector jobs for the American people.” He went on to say that the initiative would help in the “deployment of the next generation of clean-energy vehicles.”

42

Obama may be right. All-electric cars may be on the verge of grabbing a significant percentage of the U.S. car fleet.

42

Obama may be right. All-electric cars may be on the verge of grabbing a significant percentage of the U.S. car fleet.

But history shows that skepticism is in order. I'm not saying there won't be electric vehicles. There are already millions of them. In 2008, Chinese manufacturers produced some 22 million electric two-wheelers. About 65 million electric scooters are now traveling on Chinese roads. And because most of those scooters use simple lead-acid batteries instead of more expensive lithium-ion units, consumers can buy them for as little as $250.

43

43

Dozens of U.S. companies are selling electric scooters and motorcycles.

44

All-electric vehicles have become so commonplace that in early 2009, a Costco store in south Austin started selling an all-electric scooter for less than $1,000. Some of the all-electric cars now being developed will gain loyal customers, particularly among the rich. The ongoing advancements in battery technology will make electric vehicles more viable. And those improvements will be augmented by ultracapacitors.

Unlike batteries, ultracapacitors are not reliant on chemical reactions to store energy. Instead, they store electricity by physically separating the negative charge from the positive charge. (Batteries separate the two charges chemically.)

45

A key advantage of ultracapacitors is their ability to be charged and discharged very quickly, a process that tends to damage conventional batteries. By pairing batteries with ultracapacitors, automakers can assure high power delivery to the wheels and do so without wearing out the batteries.

46

44

All-electric vehicles have become so commonplace that in early 2009, a Costco store in south Austin started selling an all-electric scooter for less than $1,000. Some of the all-electric cars now being developed will gain loyal customers, particularly among the rich. The ongoing advancements in battery technology will make electric vehicles more viable. And those improvements will be augmented by ultracapacitors.

Unlike batteries, ultracapacitors are not reliant on chemical reactions to store energy. Instead, they store electricity by physically separating the negative charge from the positive charge. (Batteries separate the two charges chemically.)

45

A key advantage of ultracapacitors is their ability to be charged and discharged very quickly, a process that tends to damage conventional batteries. By pairing batteries with ultracapacitors, automakers can assure high power delivery to the wheels and do so without wearing out the batteries.

46

Though improvements in batteries and ultracapacitors will undoubtedly continue, and hybrid-electric cars will continue gaining in popularity and market share, it's worth questioning the environmental impacts of the all-electric car. An October 2009 analysis by the National Academy of Sciences looked at the environmental costs associated with various types of automobile fuel. The scientists at the National Academy looked at thirteen different fuel sources and analyzed their total impact on the environment, particularly those relating to what they called the “health and non-climate damages” for different combinations of fuels and vehicles. They then expressed those damages in cents per vehicle mile traveled (VMT) for two years: 2005, and estimates for 2030. The graph in

Figure 29

combines the data from two charts published by the academy. For the sake of simplicity, I reduced the number of fuels displayed from thirteen to nine. The figure clearly shows that vehicles powered by politically favored fuels such as corn ethanol (E85) and electricity impose more “damages” on society than vehicles that are powered by gasoline or natural gas. The conventional fuels are also less costly to society than plug-in hybrid-electric vehicles are, though the plug-ins are another politically popular choice. Those vehicles are identified in the figure as “Grid Dependent SI HEV.”

Figure 29

combines the data from two charts published by the academy. For the sake of simplicity, I reduced the number of fuels displayed from thirteen to nine. The figure clearly shows that vehicles powered by politically favored fuels such as corn ethanol (E85) and electricity impose more “damages” on society than vehicles that are powered by gasoline or natural gas. The conventional fuels are also less costly to society than plug-in hybrid-electric vehicles are, though the plug-ins are another politically popular choice. Those vehicles are identified in the figure as “Grid Dependent SI HEV.”

Other books

Kiss Me Kill Me by Lauren Henderson

Taming the Beast: Charles Manson's Life Behind Bars by Edward George, Dary Matera

Postal Marine 1: Bellicose by Ben Wilson

All Tomorrow's Parties by Nicole Fitton

Sneaks by B Button

The Fan-Shaped Destiny of William Seabrook by Paul Pipkin

To Love a Wicked Scoundrel by Anabelle Bryant

accidental 11 - accidentally ever after by cassidy, dakota

Framed and Hung by Alexis Fleming