Airborne (1997) (6 page)

Authors: Tom Clancy

The canopy depicted in da Vinci’s drawing is too small, and the shape would have made it terribly unstable, but it

might

have worked. There is no evidence Leonardo ever tested his device, or even experimented with models. In spite of this, the basic concept was on the proverbial drawing board, just waiting for someone to do something with it.

might

have worked. There is no evidence Leonardo ever tested his device, or even experimented with models. In spite of this, the basic concept was on the proverbial drawing board, just waiting for someone to do something with it.

Much of the technology that eventually led to the development of modern parachutes is derived from the construction of balloons. Early on, much balloon activity was centered in France. Benjamin Franklin (1706-1790) observed some of these flights while American ambassador to France, and quickly grasped the military implications of the new technology. From his observations of these flights came the quote at the beginning of this chapter. Ballooning never did emerge as a serious military force, but did encourage the development of the parachute. First as a daredevil spectacle, and later as a practical safety measure. Interestingly, prior to the first flights by heavier-than-air craft in the early 1900s, manned parachute jumps were being regularly made from moored balloons. The earliest military parachutists were balloon observers on both sides of the Western Front during World War I. These artillery spotters, in wicker baskets dangling from flammable hydrogen balloons, were terribly vulnerable to machine-gun fire from roving enemy aircraft. So the observers were equipped with crude parachutes and trained to bail out whenever an attack was threatened.

Despite parachutes being well developed and fairly reliable, few tactical aviators of the Great War ever used them. Early pursuit (fighter) aircraft of the day simply did not have the necessary lift to carry a man, the machine itself, guns, ammunition, a parachute, and other safety equipment. By 1918, though, the German Air Force had realized that parachutes could save the lives of irreplaceable and scarce veteran pilots, and began to issue them. None of the Allied air forces ever gave parachutes to tactical aviators.

A conceptual view of Leonardo da Vinci’s parachute design.

OFFICIAL U.S. ARMY PHOTO

The inter-war years were a time of slow and quiet development in parachute technology. By the opening of World War II, the state of the art in parachute development was based upon the labor of the industrious silkworm. This may seem odd in light of the then-recent development (in the 1930s) of such synthetic fibers as nylon by the DuPont Corporation. However, the first applications of nylon were limited to making household items like toothbrushes and women’s stockings. Thus, the many potential benefits of synthetic fibers to airborne warfare were to be denied until after World War II. Virtually every parachute used by airmen and paratroopers in that war was made from that most comfortable of fabrics: silk. Silk has many desirable qualities when used in parachutes. These include light weight, an extremely dense thread count (the number of fibers per inch when woven), a favorable porosity to air, and great tensile strength when woven into fabric and lines. Given a careful cycle of packing and cleaning, the World War II-era parachute could be used several dozen times with confidence.

The personnel parachutes used in World War II by most nations were fairly similar in design. Most utilized a circular canopy or shroud of woven silk cloth. Around the base of the canopy was a fabric support base called a skirt, from which the support or shroud lines hung. Usually the paratrooper would be held by a special harness, designed to spread the shock and loads of the parachute opening over the body. The harness was attached to a set of thick fabric supports called risers, which fed up to shroud lines.

The basic design of most non-steerable parachutes has changed little over the last six decades. A circular canopy chute will, once inflated, essentially fall in a straight and vertical line. Notwithstanding the effects of cross-winds, this means that if a stick (or line) of paratroops is dropped at regular intervals behind an aircraft, they will be spaced fairly evenly as they descend. Using circular parachutes also minimizes the chances of a midair collision between two or more paratroopers trying to maneuver. This is the reason why today, in an era when sport parachutists (“sky divers”) almost always use square parafoil parachutes which are steerable, the older-design circular models are always used in mass airdrops.

When packed, the parachute is attached to a tray which is mounted on the back of the paratrooper and attached to the harness. Around the tray are a series of overlapping fabric panels, which form a protective bag to keep the chute from being snagged or damaged prior to opening. When folded over, the bag flaps are secured with rubber bands and light cords (much like shoestrings). These are designed to break or fall away when the parachute is deployed, and must be replaced prior to each jump. As for the parachute itself, the actual deployment is handled by a long cord (called a static line) attached to the drop aircraft. When the jumpers exit the door of the airplane, they fall a set distance, and then the static line yanks the parachute loose from the bag, starting the deployment cycle. Use of the static line also has the advantage of taking the task of parachute deployment out of the hands of what probably is an overloaded, frightened, and potentially forgetful paratrooper. Should the back-mounted parachute (called the “main”) fail to deploy properly, the jumper can usually make use of a chest-mounted backup chute. The backup parachutes are manually deployed, and represent a second (and final!) chance should the main fail to open properly. By the middle of World War II, most nations deploying paratroopers had such equipment.

There were some differences in the parachutes used by various nations during World War II. For example, the German RZ-16/20 utilized a suspended harness arrangement, which allowed a Fallschirmjäger to fire his weapon while descending, but placed a premium on the athletic skills of the operator to avoid injury during parachute deployment and landing. By contrast, the American T-series chutes were utterly conventional, and have been little changed in today’s T-10 models. For their time, though, the early T-series chutes were fairly reliable, with good sink rates (how fast you lose altitude and hit the ground!) and maximum payloads. However, the use of parachutes to deliver loads like personnel and light cargo containers represented the upper limit of what could be achieved using natural fabrics. This meant that other means had to be developed so that heavy weapons and equipment could be delivered with airborne troops. In fact, the development of cargo gliders was the beginning of what we now call “heavy drop.” This is because higher loads would cause the natural fibers of the day to rip, tear, or break, causing the parachute to fail. Synthetic fibers would have been tougher and thus capable of handling larger loads, but their use was some years off.

The cargo gliders of the Second World War were designed to move personnel and heavier equipment like jeeps, antitank and field guns, and headquarters gear. Early on, the German airborne forces led the world in the development of specialized equipment for delivery of combat gear by air. The Germans started with the small DFS 230, which could carry ten men or a 900-kg/1,984-1b cargo load. Later, they produced the Go 242 medium glider and the huge Me 321, which could carry loads up to a light tank. The British produced similar craft, with their own Horsa medium glider and the big Hamilcar, which could carry a small Locust light tank. American efforts were somewhat more limited than the Germans and British, producing the Waco medium glider, with a similar load to the Horsa. Gliders, however, were dangerous and unreliable. Lightly built, they sometimes would break up while being towed to their landing zones. Even more likely was a dangerous crash upon landing, which could kill the crew and passengers, or destroy the cargo load. But until the development of really large synthetic cargo parachutes in the 1950s, gliders were the only way to land really big loads into a drop zone.

All that changed during the postwar period. Paratroopers were relieved to see the development of larger purpose-designed transport aircraft like the Flying Boxcars, and parachutes large enough to be able to land the largest loads they might need. These large cargo chutes made unmanned delivery of cargo and equipment both possible, and much more reliable than gliders of World War II. The key to the new cargo parachute designs was the use of synthetic fibers as the load-bearing material. The larger cargo parachutes changed the face of airborne warfare. Rather than the vulnerable gliders having to follow the paratroopers into a “hot” DZ, the heavy cargo could now be dropped just minutes ahead of the troopers. This improved the chances of achieving tactical surprise in a drop operation as well as insuring that more of the airborne’s vital equipment and supplies arrived intact. As an added bonus, the new materials, synthetics like nylon and rayon, were also used in the new generation of personnel parachutes, making them much more reliable with a much longer service life. Up to a hundred jumps can be made on a single modern synthetic T-10 parachute, which makes it quite a bargain by current defense standards.

By the 1960s, several new ideas in parachute design were beginning to make themselves known around the world. One of these was to change the shape of the parachute canopy to give it some degree of maneuverability. As mentioned previously, other than the effects of winds, the circular canopy parachutes tend to float down vertically in a fairly straight line. While desirable when dropping large units, this characteristic can become a liability when you want to drop people and things with pinpoint precision on a particular spot or thing. When the British attacked the Pegasus and Orne river bridges on D-Day, they used manned Horsa gliders which could land right on the targets. Fortunately, the Air Force and NASA were looking into the problem of maneuverable parachute systems for applications in recovering satellites and down aircrews. One of the most promising of these was the parafoil, which utilized a rectangular-shaped canopy with tunnels to channel air and provide forward thrust to the chute. By pulling down on various lines attached to the corners, the whole assembly could be maneuvered, with a fair cross-range. Quickly, the military adopted several maneuverable designs, primarily for special operations forces. Unfortunately, steerable personnel parachutes can be highly dangerous during massed unit drops. The problem is that the various jumpers tend to maneuver around, making the chances of a midair collision between troopers a distinct possibility. Thus, other than for Pathfinders and Ranger units, the forces within the 82nd and XVIII Airborne Corps use only circular canopy chutes.

A U.S. Army paratrooper descends under a T-10M main parachute canopy. This has been the standard parachute canopy since the late 1950s.

JOHN D. GRESHAM

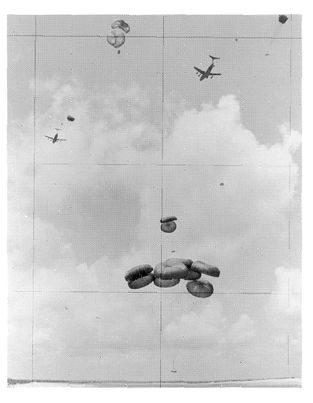

A C-17A Globemaster III deploys a series of heavy drop payloads into a drop zone. Parachute heavy drop has replaced gliders since the end of the Second World War.

OFFICIAL U.S. AIR FORCE PHOTO VIA McDONNEL DOUGLAS

AERONAUTICAL SYSTEMS

AERONAUTICAL SYSTEMS

Other books

Wonder Woman Unbound by Tim Hanley

The Virgin Billionaire’s Sexcellent Adventure by Ryan Field

The Doctor's Sex Pills by Kitty Meaker

Pixie's Passion by Mina Carter

Guy Wire by Sarah Weeks

Sleep No More by Iris Johansen

In This Life by Christine Brae

Targeted (FBI Heat) by Marissa Garner

A Twist of Fate by Demelza Hart

Touch of Temptation by Rhyannon Byrd